Polymerics liners

Polymeric liners for advanced pipeline protection

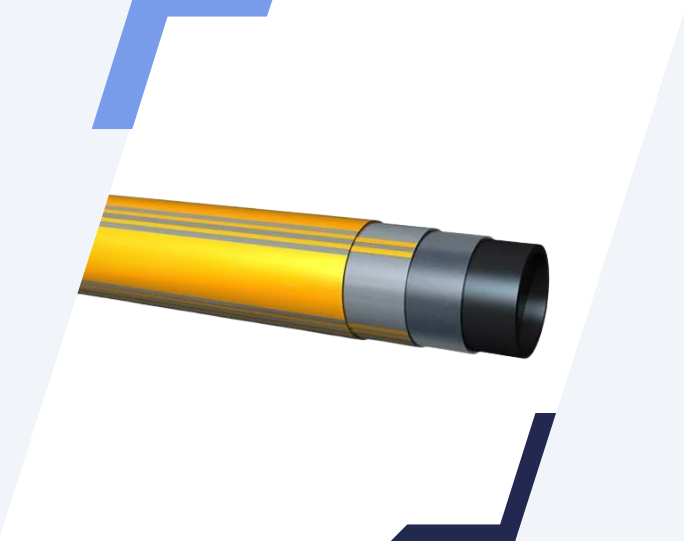

Pipeline protection with polymeric liners

Specializing in advanced pipeline protection, polymeric liners provide a cost-effective solution for preventing corrosion, enhancing durability, and improving flow efficiency in oil and gas pipelines. These liners ensure long-term reliability and reduced maintenance, making them essential for maintaining the integrity of critical infrastructure.

Mitigating pipeline corrosion in refineries with flexible HDPE liners

A refinery facing frequent internal corrosion in its aging metallic pipelines can avoid costly leaks and repairs by rehabilitating with flexible HDPE liners. This solution offers superior durability and corrosion resistance, ensuring reliable operations, reducing maintenance costs, and significantly extending the lifespan of the pipeline infrastructure.

Versatile and easy to install

Key features of HDPE pipeline rehabilitation

Efficient pipeline rehabilitation with HDPE technology

Corrosion Resistance:

Flexible HDPE pipes provide superior protection against both internal and external corrosion, ensuring an extended service life.

Quick and Safe Installation:

The flexibility of HDPE pipes allows for efficient installation, even in challenging terrains, significantly reducing downtime.

Cost Reduction:

By reusing existing infrastructure and minimizing the need for new construction, operational costs are substantially lowered.

Adaptability to Various Environments:

Ideal for both onshore and offshore applications, HDPE pipes are versatile and adapt to different operational conditions.

Unmatched Durability and Reliability

Engineered to endure high pressures and harsh environments, HDPE pipes deliver a robust and reliable solution for long-term pipeline rehabilitation.

Compliance with Industry Standards

HDPE pipes comply with stringent industry standards such as ASTM D3350 and ISO 4427, ensuring they meet the highest quality, safety, and performance requirements for pipeline applications.

Contact

If you would like more information or have any questions, please do not hesitate to contact us.

FAQ: Explore Imantt knowledge hub

Expertanswers to your common queries on RTP flexible pipes and cutting-edgetechnologies in our comprehensive FAQ section.

What advantages do RTP flexible pipes offer compared to conventional ones?

RTP pipes stand out for their strength, durability, and efficiency,surpassing conventional ones in hydrocarbon transportation.

What arethe benefits of trenchless technology in pipeline rehabilitation?

Imantt trenchless technology minimizes disruptions, reduces costs, andoptimizes pipeline integrity without the need for excavations.

How isthe installation of RTP pipes carried out, and what is their lifespan?

Our experts efficiently install RTP pipes, with a lifespan that farexceeds that of conventional alternatives.

Do youoffer monitoring and maintenance services for rehabilitated pipelines?

Yes, we provide comprehensive monitoring and maintenance services toensure the longevity and continuous efficiency of rehabilitated pipelines.

In which cases is drone technology and asset protection plates recommended?

Drone technology and asset protection plates are recommended forproactive surveillance and asset protection in critical pipeline installations,preventing potential damages.