Mcor

Advanced Mechanical Polymers for Industrial Repair and Protection

Innovative Solutions in Advanced Mechanical Polymers

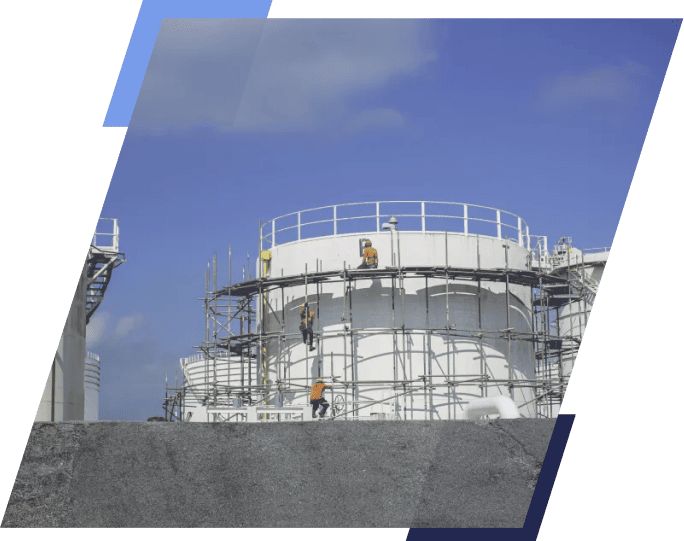

MCOR specializes in the manufacturing and supply of advanced mechanical polymers, offering innovative solutions for maintenance, repair, and protection in industrial environments. Our cold application products are designed to address a wide range of repair and coating needs, providing reliable alternatives to welding and cold bonding processes.

Key Features:

Versatile Applications:

MCOR’s products are suitable for repairing and protecting pumps, industrial structures, machinery components, and various equipment in diverse industries.

Cold Application:

Our cold application polymers offer convenience and efficiency, making them ideal for on-site repairs and maintenance tasks without the need for heat or specialized equipment

Comprehensive Solutions:

We provide a range of polymer epoxies, protective coatings, ceramic coatings, urethanes, and other advanced polymer repair systems to meet various industrial requirements.

Diverse Industries

MCOR serves industries such as mining, energy, oil and gas, food and beverage, marine, municipal water, wastewater, and more, addressing wear, abrasion, and corrosion challenges.

Global Reach:

Headquartered in Florida, USA, MCOR serves customers worldwide, offering high-quality products manufactured in the USA to ensure reliability and performance.

Additionally, Imantt is the exclusive provider of MCOR in the Americas, ensuring privileged access to these innovative solutions for customers in the region. With our expertise and MCOR’s solutions, your business can thrive with increased efficiency and durability in your industrial operations. Contact us today for more information on how MCOR can help improve your performance and productivity.

Trust Metrics: Secure Endorsemen

Explore ourreliability benchmarks, reinforcing trust through transparency, integrity, and performance excellence in every aspect of our operations

FAQs:Explore Imantt Knowledge Hub

Expertanswers to your common queries on RTP flexible pipes and cutting-edgetechnologies in our comprehensive FAQ section.

What advantages do RTP flexible pipes offer compared to conventional ones?

RTP pipes stand out for their strength, durability, and efficiency,surpassing conventional ones in hydrocarbon transportation.

What arethe benefits of trenchless technology in pipeline rehabilitation?

Imantt trenchless technology minimizes disruptions, reduces costs, andoptimizes pipeline integrity without the need for excavations.

How isthe installation of RTP pipes carried out, and what is their lifespan?

Our experts efficiently install RTP pipes, with a lifespan that farexceeds that of conventional alternatives.

Do youoffer monitoring and maintenance services for rehabilitated pipelines?

Yes, we provide comprehensive monitoring and maintenance services toensure the longevity and continuous efficiency of rehabilitated pipelines.

In which cases is drone technology and asset protection plates recommended?

Drone technology and asset protection plates are recommended forproactive surveillance and asset protection in critical pipeline installations,preventing potential damages.

Sección de testimonios

Esto es un subtitulo

“Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed egestas pharetraol quis pharetra arcu pharetra scing lectus

Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed blandit.”

“Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed egestas pharetraol quis pharetra arcu pharetra scing lectus

Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed blandit.”

“Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed egestas pharetraol quis pharetra arcu pharetra scing lectus

Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed blandit.”

“Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed egestas pharetraol quis pharetra arcu pharetra scing lectus

Lorem ipsum dolor sit amet conse ctetur adipiscing lectus a nunc mauris scelerisque sed blandit.”

Contact

If you would like more information or have any questions, please do not hesitate to contact us.

InsightsHub: Stay Updated with Imantt News

Discoverthe latest trends, innovations, and industry updates in our comprehensive hubfor valuable insights and expertise

Case study – Slipling RTP

Severe corrosion in oil pipeline In 2024, severe corrosion compromised a critical crude oil pipeline segment in Tolima, Colombia,

Case study -Emergency Response

EMERGENCY RESPONSE WITH RTP FLEXIBLE PIPELINE In 2021, a landslide in the Samoré region severely affected a crude oil

Polymeric liners / ES

La solución innovadora para la rehabilitación y/o reparación de tuberías metálicas existentes Imantt es la empresa líder en la transformación

Rehabilitation of metallic pipelines

Tuberias flexibles para transporte de gas

Tuberías flexibles de última generación para el transporte de fluidos, instalación ágil y operativas al instante. Este innovador sistema de