Non-metallic EPC infrastructure & Trenchless rehabilitation

Recover critical Oil & Gas assets using API 15S compliant RTP technology. Eliminate internal corrosion, restore and reduce installation CAPEX by up to 40% compared to carbon steel.

Emergency response with advanced RTP flexible pipelines. Ensure fast and reliable hydrocarbon transport in critical situations.

Sliplining RTP Rehab

Rehabilitation of high pressure metallic pipelines with RTP reinforced thermoplastic pipes.

Compression Fit Rehab

Rehabilitation of metallic infrastructure with thermoplastic polymeric liners

Plate-Guard

HDPE plates for underground protection of pipelines, power cables, fiber optics & critical infrastructure

Innovative EPC Solutions in Non-Metallic Pipeline Infrastructure

Engineering excellence in non-metallic systems for energy and oil & gas infrastructure projects

We develop and execute engineering, procurement, and construction projects focused on non-metallic infrastructure.

Our approach ensures efficient project delivery, reduced operational risk, and long-term performance in demanding environments.

Expertises

15 Years of Excellence: Imantt Proven Expertise in Oil and Gas Industry Innovations

EPC projects with non metallic infraestructure

Non-metallic EPC solutions: integrated engineering, procurement, and construction for durable, corrosion-resistant energy systems.

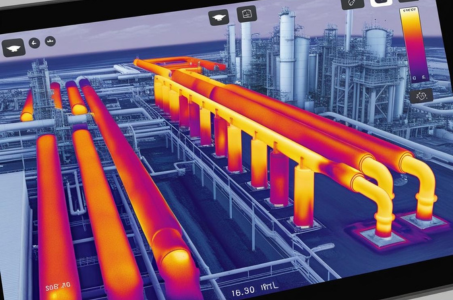

Reinforced thermoplastic piping (RTP) for hydrocarbon transportation

RTP pipeline systems: fast-deploying, corrosion-free solutions for high-pressure hydrocarbon transport.

Internal rehabilitation of pipelines with polymeric liners - Trenchless technology

Non-metallic lining systems: extend service life and restore integrity of aging metallic pipelines.

APC

Polymer coating technology: safe storage, protection, and transport of aggressive chemicals.

Mcor

High-performance polymer systems: corrosion protection for metal surfaces in oil, gas, and chemical infrastructure.

Drone-Guard

AI-powered drone inspection: real-time monitoring and integrity management for oil and gas infrastructure.

HDPE plates

HDPE protection plates: impact-resistant shielding for underground pipelines, valves, and energy infrastructure.

Trust metrics

Boxing classes

Specialized EPC Experience

Boxing classes

RTP Pipelines Deployed

Boxing classes

Reported Operational Failures

Technical FAQ & Engineering Insights

Expertanswers to your common queries on RTP flexible pipes

What is the high-pressure alternative to Carbon Steel for flowlines?

RTP pipes stand out for their strength, durability, and efficiency,surpassing conventional ones in hydrocarbon transportation.

How can I rehabilitate a corroded pipeline without open-trench excavation?

Corroded assets are rehabilitated using Imantt Trenchless Sliplining. This methodology utilizes the existing damaged pipeline as a “host casing.” We pull a continuous, flexible RTP liner through the old pipe, restoring the Maximum Allowable Operating Pressure (MAOP) and fluid containment integrity without the environmental impact or high civil works costs of traditional “dig-and-replace” methods.

What is the service life comparison between RTP and Carbon Steel?

Carbon steel flowlines typically require major maintenance or replacement every 15 to 20 years due to electrochemical corrosion and MIC (Microbiologically Influenced Corrosion). In contrast, Imantt RTP systems offer a verified Design Life of 50+ years with zero derating over time, as verified by ASTM D2990 long-term hydrostatic strength testing.

Do youoffer monitoring and maintenance services for rehabilitated pipelines?

Yes, we provide comprehensive monitoring and maintenance services toensure the longevity and continuous efficiency of rehabilitated pipelines.